-

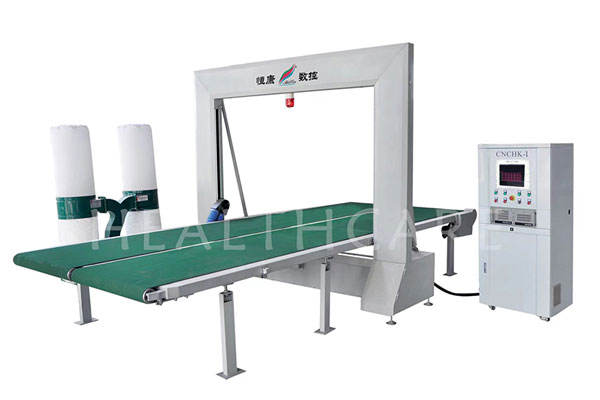

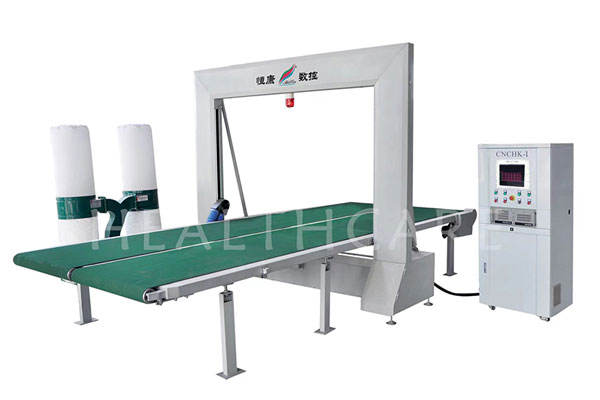

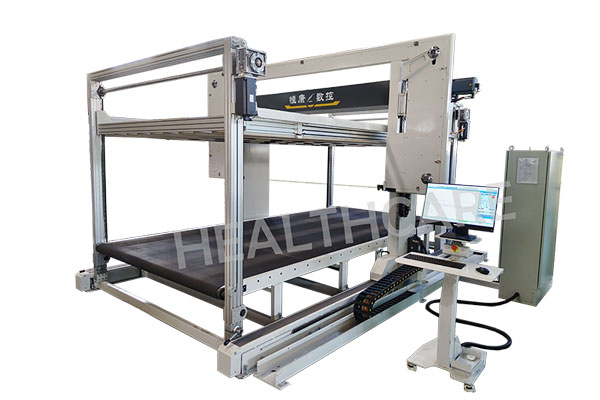

- CNCHK-1 is the first generation of CNC foam cutting machine in our company, and is also the first one in the Chinese foam contour cutting industry. This foam processing machine features simple operation and high cutting speed, which is widely used in the production of automobile parts, upholstered furniture, and mattresses, as well as in the packaging and insulation industries.Learn More

-

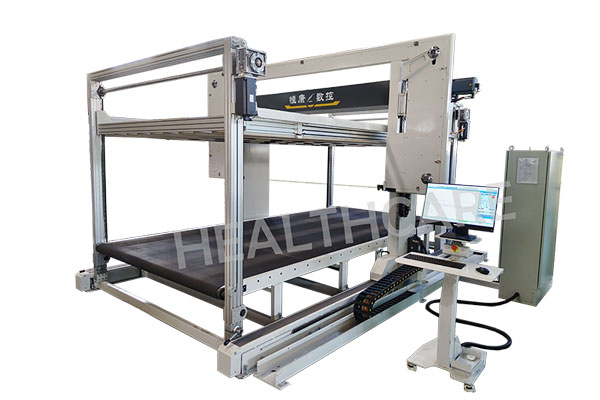

- The CNC foam cutting machine adopts oscillating blade for good cutting results, which is the second generation of foam cutter self developed by our company. This foam processing machine realizes horizontal CNC contour cutting without generating foam dust. Featuring compact construction and flexibility, the foam cutter provides fast cutting with high precision.Learn More

-

- CNCHK-3 CNC foam cutting machine uses vertical blade for foam contour cutting with high speed and precision, which is a good alternative to foam die cutting machine. With cut-off and trimming unit, the CNC foam cutter is ideal for use in the production of automobile parts, upholstered furniture, and mattresses, as well as in the packaging and insulation industries. Learn More

-

- CNCHK-4 horizontal CNC contour cutter is designed with turntable, providing high flexibility adapting to double-sided foam contour cutting in an efficient manner. Because of high cutting accuracy, dust-free cutting and simple operation, this CNC foam cutting machine is ideally suitable for use in the production of upholstered furniture, mattress, automotive seating, etc. Learn More

-

- CNCHK-5 CNC foam cutting machine is developed based on the CNCHK-2, with added vertical blade, which is used for simple 3D contour cutting. The contour cut parts by the foam cutter are a great alternative to die cut parts by foam die cutting machine.Learn More

-

- The vertical blade foam contour cutting machine features automated foam cutting CNC technology, resulting in various advantages for foam fabrication including improved dimensional accuracy, increased cutting speed, consistency of contoured parts, reduced foam dust.Learn More

-

- The advantage of the horizontal continuous blade contour cutting machine is its cutting speed, which is 3-5 times that of horizontal oscillating blade for contour cutting foam materials with ordinary hardness. This CNC foam cutting machine is designed with automatic foam size measuring device, roll compression unit with induction, automatic turntable, etc.Learn More

-

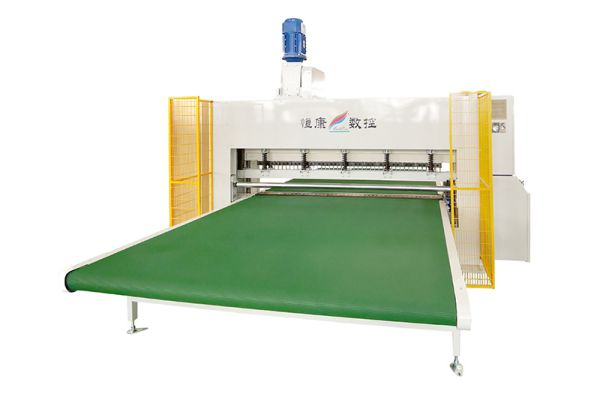

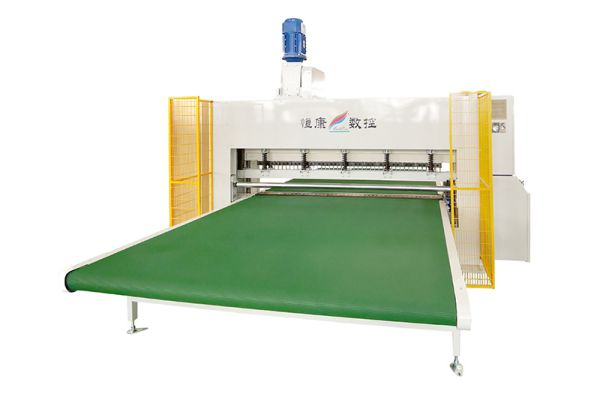

- Horizontal splitting machine is mainly used for layered cut of ordinary foam, memory foam, industrial foam, etc. The cut foam materials are well stacked without human intervention. Featuring high accuracy and efficiency, this foam processing machine can be connected with vertical continuous blade contour cutting machine to form a cutting line, greatly improving working efficiency and reducing labor cost.Learn More

-

- CNCHK-10 is the first roller gluing machine in the Chinese market. This roll coating machine can automatically check the foam thickness to adjust the working height of roller. The glue is applied on the foam evenly. After glue application, roll-packing can be performed in a short time.Learn More

-

- In foam factory, block storage rack system plays an important role in the storage of foam blocks after foaming and cut-off. This automatic storage system saves foam curing time, provides maximize space utilization, and prevent foams from scorching. What's more, it can transport super soft foam which can't be lifted by the clamp. Learn More

-

- After punching, the foam debris in the hole can be automatically removed, ensuring continuous punching. The hole distance can be slightly adjusted with ease of operation. The foam hole punching machine can be used as a stand-alone machine or configured with a cutting machine to create a cutting line.Learn More

Healthcare Machinery offers vertical, horizontal and wire CNC contour cutting machines for profile cutting rigid, semi-rigid and flexible polyurethane foams. We are an industry leader with improved dimensional accuracy, increased cutting speed, consistency of contoured parts, reduced foam dust, improved material yield, and improved operator safety. Foam contour cutters are rugged, fast, accurate, easily operated, easily serviced and are offered at competitive prices. Cutting edge CNC Contour machines allow us to produce virtually any 2D shapes or contours/parts in large volumes, with a high degree of repeatability. Our contour machines can cut a variety of material types such as polyurethane foams, polyethylene foams, polyester fiber and many composite materials. The latest in CNC technology allows our engineering staff to quickly convert customer drawings, prints and samples into finished products. Automatic profile nesting software ensures we can attain the highest possible material yield which increases efficiency and reduces cost.