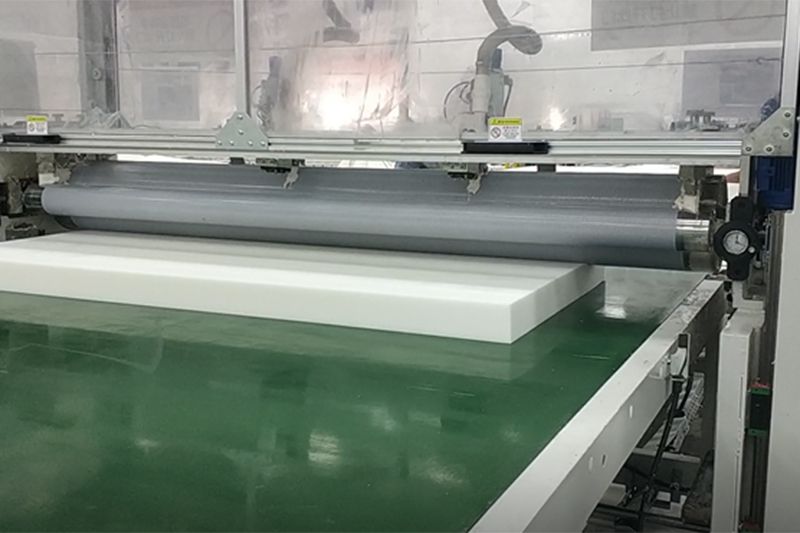

Gluing Machine/Roll Coater, CNCHK-10

Roll Coating Machine for Foam Bedding Products with Water-Based Adhesive

CNCHK-10 is the first roller gluing machine in the Chinese market. This roll coating machine can automatically check the foam thickness to adjust the working height of roller. The glue is applied on the foam evenly. After glue application, roll-packing can be performed in a short time. This roll coating machine can be paired with mattress production lines.

Technical Data

| Machine size | 4800x3350x2000mm | Touch screen | Mitsubishi |

| Weight | 2.0t | PLC | Mitsubishi /Omron |

| Width | 100-2100mm | Inverter | Mitsubishi |

| Thickness | 10-300mm | Power supply | 6.5kW, 380V, 50Hz |

| Conveyor speed | 0-28m/min | Glue type | Water-based glue |

| Glue consumption | 50-60g/㎡ | Automatic glue supply system | Installed |

Features

- Automatic glue supply for improved working efficiency

- Adjustable width for glue application reduces glue consumption.

- Foam thickness can be detected by sensors, and roller will go up/down automatically.

- No glue overflow occurs after glue application, causing no pollution to the working environment.

- High production rate: 800pcs/day for 2-layer mattress; 600pcs/day for 3-layer mattress

- It can be upgraded to an automatic mattress production.

Applications

- Foam Mattress Factory

Standard

- Automatic measuring system for foam height and length

- Automatic glue supply device

- Optional manual and automatic operation

Options

- Configured into the mattress production line with added press machine, trimming machine, conveyor and stacking unit.